Specialized Production 3

Extensive Production Capacity System

Blending Workshop: It includes three major blending workshops for powders, wax-based, and comprehensive products. This comprises over 100 pieces of equipment such as vacuum emulsifying kettles, vacuum deaeration melting systems, ultrafine air pulverizers, high-speed powder homogenizers, and high-speed dispersion systems.

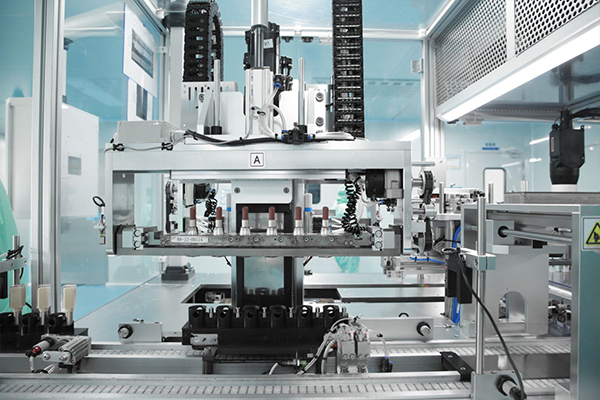

Production Systems: Encompassing skincare production, wax-based filling, powder canning, Low-temperature 3D precision dehydration, and BFS (Blow-Fill-Seal) - a total of over 400 pieces of production equipment.

Packaging Department: Comprising 50 packaging assembly lines, including 15 for powder packaging, 35 for cream-based packaging, and over 200 packaging machines.